A Magnetic Linear Position Transducerr, also known as a linear magnetic encoder or magnetic linear displacement sensor, is a type of sensor used to measure the linear displacement or position of an object. These sensors utilize the interaction between magnetic fields to determine the position of a magnetic target along a linear path. They are widely used in various industrial applications for accurate and reliable position sensing. Here's an overview of how magnetic linear position .

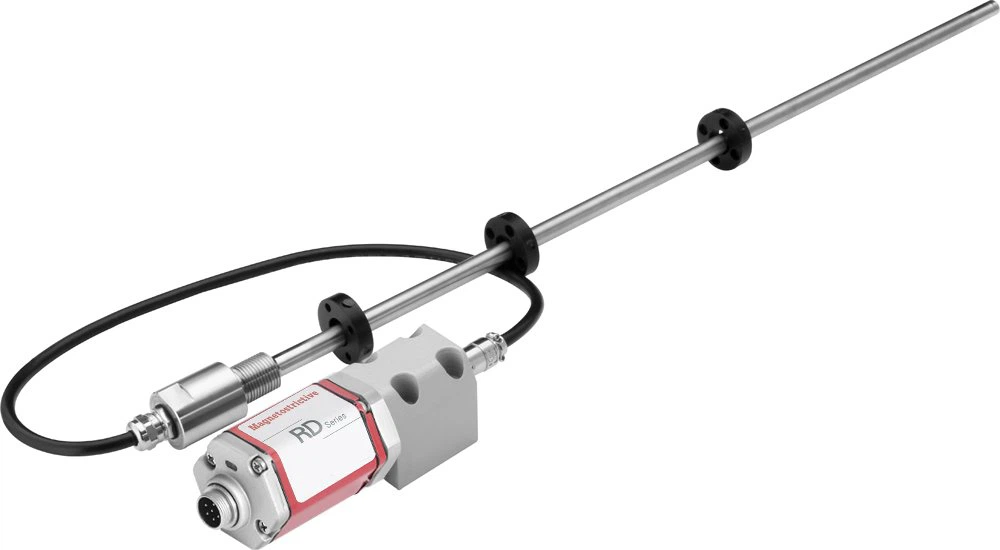

Magnetic Target: A magnetic linear position sensor typically consists of two main components: a sensor element and a magnetic target. The magnetic target is attached to the object whose position needs to be measured. It contains one or more magnets with a specific magnetic pattern.

Sensor Element: The sensor element is placed adjacent to the magnetic target and consists of a magnetic field sensor, such as a Hall effect sensor or magnetoresistive sensor. These sensors are sensitive to changes in magnetic fields.

Magnetic Field Detection: As the magnetic target moves along the linear path, the magnetic field sensor detects changes in the magnetic field pattern produced by the magnets on the target.

Non-Contact Operation: Magnetic linear position sensors operate without physical contact between the sensor and the target, minimizing wear and tear.

High Accuracy: These sensors offer high accuracy and resolution in measuring linear displacement.

Robustness: Magnetic sensors are resistant to dust, dirt, and contaminants, making them suitable for various industrial environments.

Industrial automation: Monitoring the position of moving parts in machinery and equipment.

Automotive: Measuring the position of vehicle components such as throttle pedals and suspension systems.

Robotics: Monitoring the position of robotic arms, grippers, and joints.

Aerospace: Tracking the position of control surfaces and mechanisms in aircraft.

Material handling: Monitoring conveyor belt positions and other moving components.